Table of Contents

Product Overview

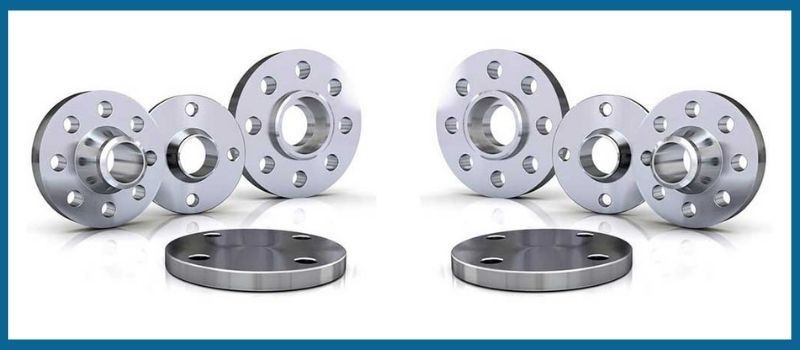

ASTM B564 Inconel 600 Blind Flanges, Inconel DIN 2.4816 Slip on Flanges, Alloy 600 SWRF Flanges Suppliers in India.

UNS N06600 Orifice Flanges, Inconel 600 Weld Neck Flanges Exporter, 600 Inconel RTJ Flange Leading Manufacturer.

Sankalp Alloys Overseas is one of the best exporter, creator and provider of Inconel 600 Flanges in India. Inconel boasts excellent qualities compared to most alloys, including stainless steel. Their higher cost compensates with high mechanical strength and excellent corrosion resistance properties. Generally, Inconel Flanges are used to serve in environments of elevated temperatures. Unlike most alloys that lose dimensional stability and mechanical properties at high temperatures, Inconel retains its performance. For example, Inconel 600 resists inert atmospheres up to 2000°F, which makes it excellent for highly demanding applications.

Besides high-temperature features, Inconel has excellent performance even at low temperatures. This UNS N06600 Long Weld Neck Flange has good impact strength that enables it to be used at cryogenic temperatures to low temperatures. Its comprehensive temperature range performance is combined with the excellent corrosion resistance of the alloy.

It resists in an oxidizing environment and the presence of sulfur-bearing compounds. A Nickel Alloy 600 Weld Neck Flange performs better than commercially pure nickel in oxidizing conditions due to its content of a sufficient amount of chromium. The addition of chromium increases ASTM B564 UNS N06600 Blind Flange's resistance against oxidation. Sankalp Alloys Overseas proposes Inconel 600 since it is an all-purpose and dependable alloy at high and low temperatures, apart from its sturdy resistance to corrosive environments.

Inconel 600 Flanges Manufacturers in Mumbai, Inconel 600 Flanges Suppliers in Mumbai, Inconel 600 Flanges Stockists in Mumbai, Inconel 600 Flanges Exporters in Mumbai

ANSI B16.5 INCONEL 600 FLANGES SPECIFICATION

| Parameter | Details |

|---|---|

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Standards | ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc. |

| Specifications | ASTM B564 / ASME SB 564 |

| Size | 1/2" to 36″ |

| Class | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Grade | Inconel 600 – UNS N06600 |

| Additional | Our Inconel 600 Flanges conforms to NACE MR0175/ISO 15156 |

ASTM B564 INCONEL 600 FLANGES EQUIVALENT GRADES

| Standard | Grade |

|---|---|

| WERKSTOFF NR. | 2.4816 |

| UNS | N06600 |

| GOST | МНЖМц 28-2,5-1,5 |

| AFNOR | NC15FE11M |

| JIS | NCF 600 |

| BS | NA 13 |

| EN | NiCr15Fe |

| OR | ЭИ868 |

INCONEL ALLOY 600 FLANGES CHEMICAL COMPOSITION

| Element | Composition (%) |

|---|---|

| Ni | 72.0 min |

| Cr | 14.0 – 17.0 |

| Fe | 6.0 – 10.0 |

| C | 0.15 max |

| Mn | 1.0 max |

| S | 0.015 max |

| Si | 0.5 max |

| Cu | 0.5 max |

600 INCONEL ALLOY PIPE FLANGES MECHANICAL PROPERTIES

| Property | Value |

|---|---|

| Density | 8.47 g/cm3 |

| Melting Point | 1413 °C (2580 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 |

| Elongation | 40 % |

OUR EXPORT AREAS

| Eastern Europe | Asia | North America | Western Europe | Mid East/Africa |

|---|---|---|---|---|

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

DOMESTIC AREAS

| Western India | Northern India | Southern India | Eastern India | Central India |

|---|---|---|---|---|

| Mumbai | Delhi | Chennai | Kolkata | Bhopal |

| Pune | Bikaner | Bangalore | Siliguri | Indore |

| Ahmedabad | Nagpur | Hyderabad | Assam | Raipur |

| Surat | Thane | Coimbatore | Visakhapatnam | Bhilai |

| Nashik | Faridabad | Mysore | Cochin | Ankleshwar |

| Aurangabad | Rajkot | Salem | Bhubaneswar | Bhiwandi |

| Bhavnagar | - | Tirupur | Kochi | Mangalore |

| Vadodra | - | - | - | - |

People in Maharashtra & India Also Search For

Inconel 600 Flanges Maharashtra, Inconel Flanges Mumbai, Industrial Flanges Pune, ASTM B564 Flanges Nashik, Alloy Flanges Aurangabad, Metal Flanges Thane, Industrial Components Navi Mumbai, Manufacturing Companies Maharashtra, Inconel 600 Flanges